Amavalvu okulawula umshayeli we-hydraulic adlala indima ebalulekile ezinhlelweni zesimanje ze-hydraulic ngokulawula ukugeleza koketshezi nokuqinisekisa ukuphepha kokusebenza. Lawa mavalvu ahlinzeka ngokugeleza okulandela indlela eyodwa futhi avimbele ukugeleza okubuyela emuva ngaphandle kokuthi kusetshenziswa ingcindezi yomshayeli. Izimboni ezifana nezimoto kanye nezindiza ziyazamukela ngokwandayo ngenxa yokusebenza kahle kwazo ezindaweni ezinomfutho ophezulu. Ukuhlanganiswa kwezinto ezithuthukisiwe kanye nobuchwepheshe kuye kwathuthukisa ukusebenza kwazo. Isibonelo, ezinhlelweni ezifanauchungechunge lwezibambo zevalvu yokulawula umshayeli wendiza yomvukuzi, la ma-valve okulawula i-hydraulic pilot aqinisekisa ukulawula okunembile nokuthembeka. Ngaphezu kwalokho, isidingo esikhulayo se-induku yokudlala yokulawula umshayeli we-hydraulicIzixazululo emikhakheni yezimboni zigcizelela ukubaluleka kwazo ekugcineni uzinzo lwesistimu.

Izinto Ezibalulekile Okufanele Uzicabangele

- Ama-valve okushayela amanzi ahamba ngendlela eyodwa kuphela. Lokhu kumisa ukugeleza kwamanzi futhi kugcina uhlelo luphephile.

- Ukunakekela la ma-valve kubalulekile njalo. Kuzisiza ukuthi zisebenze kahle futhi zihlale ziphephile isikhathi eside.

- Lawa ma-valve enza izinhlelo zisebenze kangcono ngokulawula ukugeleza koketshezi ngqo.konga amandla amaningiemafektri.

Isebenza kanjani ivalvu yokulawula umshayeli we-hydraulic?

Isimo esizenzakalelayo kanye nokugeleza kwendlela eyodwa

A i-valve yokulawula umshayeli we-hydraulicisebenza esimweni esizenzakalelayo esivumela uketshezi ukuthi lugeleze ohlangothini olulodwa kuphela. Lokhu kugeleza kwendlela eyodwa kutholakala ngendlela efakwe entwasahlobo egcina ivalvu ivaliwe ngaphandle kokuthi kuhlangatshezwane nezimo ezithile zokucindezela. Intwasahlobo isebenzisa amandla ku-poppet yangaphakathi yevalvu, ivimbela ukugeleza okuphambene ngaphansi kwezimo ezijwayelekile. Lapho ukucindezela koketshezi endaweni yokungena kudlula amandla entwasahlobo, ivalvu iyavuleka, okwenza uketshezi ludlule.

Ithebula elingezansi libonisa ukuthi isimo esizenzakalelayo kanye nokugeleza kwendlela eyodwa kusebenza kanjani ngaphansi kwezimo zokusebenza ezahlukahlukene:

| Incazelo Yobufakazi | Incazelo |

|---|---|

| I-valve yokuhlola eyisisekelo ivumela uketshezi ukuthi lugeleze ohlangothini olulodwa, kulokhu kusukela phansi kuya phezulu. | Lokhu kubonisa umsebenzi wokugeleza kwe-valve ohamba ngendlela eyodwa, okuqinisekisa isimo sayo esizenzakalelayo sokuvimbela ukugeleza okuphambene ngaphandle kokuthi kuhlangatshezwane nezimo ezithile. |

| Isiphethu sigcina uketshezi lungagelezi ngaphandle kokuthi ingcindezi engezansi esebenza ku-poppet inqobe amandla esiphethu. | Lokhu kugqamisa indlela esebenza ngayo egcina isimo esizenzakalelayo sevalvu, okuqinisekisa ukuthi ivuleka kuphela ngaphansi kwezimo ezithile zokucindezela. |

Ngaphezu kwalokho:

- Ukucindezela emuva endaweni yokungena kuphikisana ngqo nokucindezela komshayeli, okwandisa ukucindezela okudingekayo ukuvula ivalvu.

- Ukunyakaza kwe-actuator okungajwayelekile kungase kwenzeke uma ukucindezeleka kwangemuva kuhlobene nokugeleza, okugcizelela isidingo sezimo zokusebenza eziqondile.

- Isilinganiso somshayeli osebenzayo sihlala singaphansi kwesilinganiso sendawo, okudinga ukuphathwa ngokucophelela kwengcindezi yomshayeli ukuze kusebenze kahle ivalvu.

Indima yokucindezela komshayeli ekuvuleni ivalvu

Ingcindezi yomshayeli idlala indima ebalulekileekusebenziseni ivalvu yokulawula umshayeli we-hydraulic. Uma isetshenziswa, ilwa namandla esiphethu, ivumela ivalvu ukuthi ivuleke futhi uketshezi lugeleze ngendlela ephambene uma kudingeka. Lesi sici siwusizo kakhulu ezinhlelweni ezidinga ukugeleza okulawulwayo kwezinhlangothi zombili, njengokusetshenziswa kokubamba umthwalo.

Idatha yokuhlola iqokomisa ithonya lokucindezela komshayeli ekusebenzeni kwevalvu. Isibonelo:

| Incazelo Yobufakazi | Okutholakele |

|---|---|

| Ukusebenza kwama-PRV aqhutshwa yi-pilot ngaphansi kwezimo zesidingo eziguquguqukayo | Ukucindezela komshayeli kuthonya ukusebenza kwama-valve, kuthinta ukulawulwa kwengcindezi kanye nokusabela ekushintsheni kokugeleza. |

| Ukuqhathaniswa kwesicelo sensimu phakathi kwe-PRV eqhutshwa yi-pilot kanye ne-GVS | I-GVS ikhombisa ukwehla kwezinga lokucindezela futhi igcina ingcindezi elawulwayo iseduze kakhulu nenhloso uma kuqhathaniswa ne-PRV eqhutshwa yi-pilot. |

| Ukuhlolwa kokusebenza kahle kokulawula ingcindezi | Ucwaningo luqhathanisa ukusebenza kwamavalvu okulawula azenzakalelayo ahlukene, luqokomisa indima yokucindezela komshayeli ekugcineni ingcindezi elawulwayo. |

Lokhu okutholakele kubonisa indlela ingcindezi yomshayeli eqinisekisa ngayo ukuthi ivalvu isabela kahle ezidingweni zesistimu ezahlukahlukene, okuthuthukisa ukusebenza kwayo kahle.

Indlela yokuvimbela ukugeleza emuva

Ivalvu yokulawula umshayeli we-hydraulic ifaka indlela eqinile yokuvimbela ukugeleza emuva. Le ndlela incike ku-spring-loaded poppet, evala ivalvu lapho umfutho woketshezi wehla ngaphansi kwamandla espring. Ngokwenza kanjalo, iqinisekisa ukuthi uketshezi alukwazi ukugeleza ngendlela ephambene, igcine ukuzinza kohlelo futhi ivimbele ukulimala okungenzeka ezingxenyeni.

Imibhalo yobuchwepheshe iqinisekisa le ndlela. I-hydraulic check valve isebenza njenge-valve enendlela eyodwa, ivuleka kuphela lapho umfutho woketshezi udlula amandla entwasahlobo. Lapho umfutho wehla ngaphansi kwalo mkhawulo, amandla entwasahlobo ayayivala i-valve, ivimbele ngempumelelo ukugeleza okubuyela emuva. Lo mklamo uqinisekisa ukusebenza okuthembekile ngisho nangaphansi kwezimo zokucindezela ezishintshashintshayo, okwenza kube yinto ebalulekile ezinhlelweni ze-hydraulic ezibalulekile ekuphepheni.

Izinzuzo zamavalvu okulawula umshayeli we-hydraulic

Ukuvimbela ukugeleza kwegazi emuva nokuqinisekisa ukuphepha

Amavalvu okulawula umshayeli we-hydraulic adlala indima ebalulekile ku-ukuvimbela ukugeleza emuva, okubalulekile ekugcineni ukuphepha kwezinhlelo ze-hydraulic. Ngokusebenzisa indlela ye-spring-loaded poppet, lawa ma-valve aqinisekisa ukuthi uketshezi lugeleza kuphela ngendlela ehlosiwe. Lo mklamo unciphisa ingozi yokugeleza okuphambene, okungase kuholele ekungasebenzi kahle kwesistimu noma ekulimaleni kwezingxenye ezibucayi. Ezisetshenzisweni ezibalulekile zokuphepha, njengezindiza noma imishini yezimboni, lesi sici siba yinto ebaluleke kakhulu.

Ikhono lala ma-valve lokuvimba ukugeleza okuphambene livikela nabasebenzi kanye nemishini ezingozini ezingaba khona. Isibonelo, ezinhlelweni zokubamba umthwalo, i-valve ivimbela ukunyakaza okungahlosiwe kwama-actuator, iqinisekisa ukuthi imithwalo ihlala iphephile endaweni yayo. Leli zinga lokuphepha libalulekile ezindaweni lapho ukunemba nokuthembeka kungaxoxiswana ngakho.

Ithiphu: Ukugcinwa njalo kwama-valve okulawula umshayeli we-hydraulic kungathuthukisa kakhulu ikhono lawo lokuvimbela ukugeleza kwamanzi emuva, okuqinisekisa ukuphepha kohlelo isikhathi eside.

Ukugcina ukuzinza kwesistimu ngaphansi komthwalo

Ama-valve okulawula umshayeli we-hydraulic anegalelo elikhulu ekugcineni ukuzinza kohlelo, ikakhulukazi ngaphansi kwezimo zomthwalo oguquguqukayo. Amandla awo okulawula ukugeleza koketshezi ngokunemba aqinisekisa ukuthi izinhlelo ze-hydraulic zihlala zilinganisela, ngisho noma zingaphansi kwezingcindezi noma amandla ahlukahlukene. Lokhu kuzinza kubalulekile ekusetshenzisweni okufana nemishini yokwakha, lapho imithwalo engalingani ingafaka khona ukusebenza kabi.

Izilinganiso zokusebenza ziqokomisa ukusebenza kahle kwala ma-valve ezinhlelweni zokuzinzisa. Isibonelo:

| Uhlobo Lobufakazi | Incazelo |

|---|---|

| Izilinganiso Zomshayeli Wezindiza | Izilinganiso zokulawula eziphakeme zithuthukisa izikhathi zokuphendula, zithuthukisa ukuzinza komthwalo. |

| Izikhathi Zokuphendula | Izifundo zibonisa izikhathi ezifile eziphansi njengemizuzwana eyi-1.4, okubonisa ukusabela okusheshayo. |

| Isicelo Somhlaba Wangempela | Izifundo ze-NASA ne-FAA zibonisa ukuzinza okuthuthukisiwe ezindaweni ezibucayi. |

Lokhu okutholakele kugcizelela ukubaluleka kwama-valve okulawula umshayeli we-hydraulic ekuqinisekiseni ukusebenza okulinganayo ngaphansi komthwalo. Amakhono abo okuphendula ngokushesha kanye nokuzivumelanisa nezimo kubenza babe ukukhetha okuthandwayo kwezimboni ezidinga amazinga aphezulu okunemba nokuthembeka.

Ukuthuthukisa ukusebenza kahle kanye nokulawula

Ama-valve okulawula umshayeli we-hydraulic nawo asebenza kahle kakhuluukuthuthukisa ukusebenza kahlekanye nokulawulwa kwezinhlelo ze-hydraulic. Ngokuvumela ukulawulwa okunembile kokugeleza koketshezi, kunciphisa ukusetshenziswa kwamandla futhi kuthuthukise ukusebenza kohlelo lonke. Lokhu kusebenza kahle kubonakala kakhulu ezisetshenziswa zezimboni nezakhiwo zanamuhla.

Ukuhlaziywa kokuqhathanisa kwembula ukonga okukhulu kwamandla okutholakale ngokusebenzisa la ma-valve:

- Ukuhlanganiswa kwamasilinda amathathu alawulwa yinjini (ama-MCC) ku-crane yezimboni yokufaka amapayipi kunciphisa ukusetshenziswa kwamandla ngo-83.4% uma kuqhathaniswa nezinhlelo zendabuko ezilawulwa ngama-valve.

- Abavubukuli abahlonyiswe ngama-MCC ayisithupha bathole ukonga amandla ngo-47.8% uma kuqhathaniswa nalabo abasebenzisa amasilinda alawulwa ngamavalvu.

Lezi zibonelo ziqokomisa indlela ama-valve okulawula i-hydraulic pilot anikela ngayo ekusebenzeni okusimeme nokungabizi kakhulu. Ikhono lawo lokunikeza ukulawula okunembile liphinde lithuthukise ulwazi lomsebenzisi, olwenza opharetha bakwazi ukwenza imisebenzi ngokunemba okukhulu nangokuzethemba.

Inothi: Ukwamukelwa kwezinto zokwakha kanye nobuchwepheshe obuthuthukisiwe kuma-valve okulawula umshayeli we-hydraulic kuthuthukisa ukusebenza kwawo kahle, okwenza abe yimpahla ebalulekile ezinhlelweni zesimanje ze-hydraulic.

Ukusetshenziswa kwama-valve okulawula umshayeli we-hydraulic

Ukusetshenziswa kwemishini yokwakha yokubamba umthwalo

Ama-valve okulawula umshayeli we-hydraulic akhonaokungabalulekanga kakhulu emishini yokwakha, ikakhulukazi kwezicelo zokubamba umthwalo. Lawa ma-valve aqinisekisa ukuzinza ngokugcina ingcindezi yokushayela engaguquki, okuvimbela izimo zomthwalo odlulayo. Ikhono lawo lokulawula ukugeleza koketshezi ngokunemba liwenza abaluleke kakhulu emishinini esindayo njengama-crane kanye nemishini yokumba.

Izici ezibalulekile zokusebenza zifaka:

- Amavalvu okulawula umthwalo alinganiselayo azinzisa ukubamba umthwalo ngokugcina ingcindezi yomshayeli engaguquki.

- Izihlukanisi ze-orifice zilawula ngempumelelo ingcindezi yokuqala, zinciphisa izingozi zokungazinzi.

- Izinhlelo zokusebenza ze-Federated Crane zibonisa isidingo sokulungiswa kokulawula okunembile kumasekethe okugcina umthwalo.

Lawa makhono athuthukisa ukuphepha nokusebenza kahle, okuqinisekisa ukuthi imishini yokwakha isebenza ngokwethembeka ngaphansi kwezimo zomthwalo ezahlukahlukene.

Izicelo ezinhlelweni zokukhiqiza nezezimboni

Ezinhlelweni zokukhiqiza nezezimboni, ama-valve okulawula umshayeli we-hydraulic adlala indima ebalulekile ezenzakalelayo kanyeukusebenza kahle kwamandla. Zivumela ukulawulwa okunembile kokugeleza koketshezi, okubalulekile ekugcineni ukusebenza okulinganayo ezinqubweni ezenzakalelayo. Izimboni ziya ngokuya zisebenzisa la ma-valve ukuze zihlangabezane nezidingo zamandla ezikhulayo futhi zithuthukise umkhiqizo.

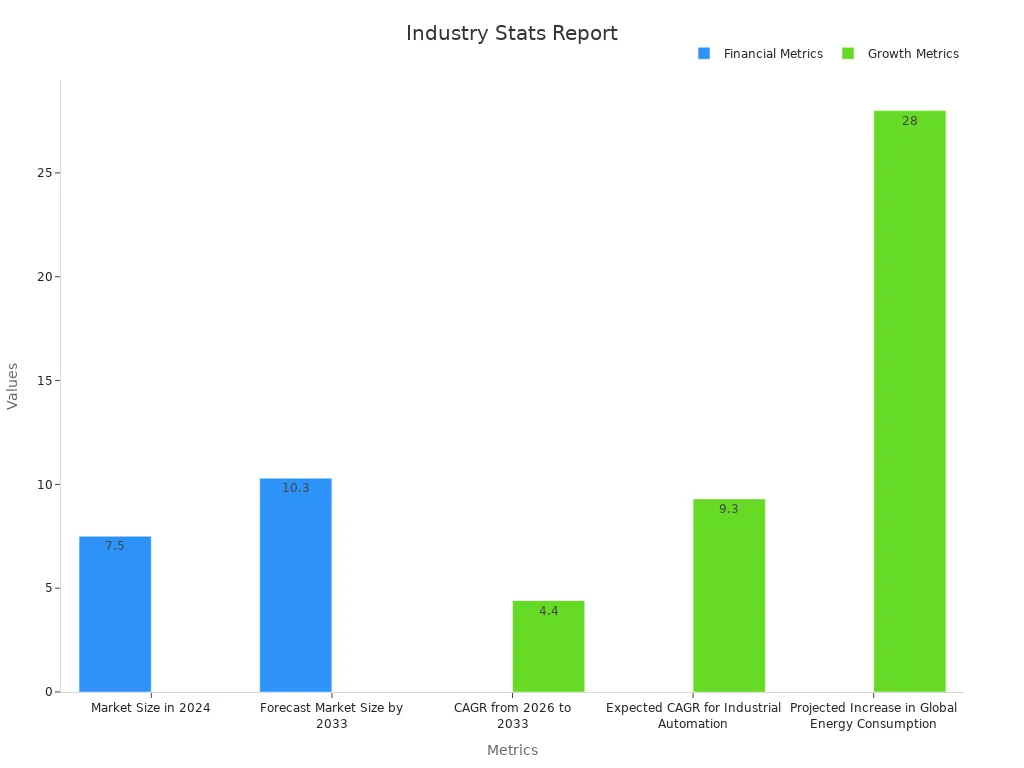

Imakethe yama-valve okulawula umshayeli we-hydraulic ikhombisa ukwamukelwa kwawo kabanzi:

| I-Metric | Inani |

|---|---|

| Usayizi Wemakethe ngo-2024 | Ama-USD ayizigidigidi eziyi-7.5 |

| Usayizi Wemakethe Wesibikezelo ngo-2033 | Ama-USD ayizigidigidi eziyi-10.3 |

| I-CAGR kusukela ngo-2026 kuya ku-2033 | 4.4% |

| I-CAGR Elindelekile Yokuzenzakalela Kwezimboni | 9.3% kuze kube ngu-2025 |

| Ukwanda Okulindelwe Ekusetshenzisweni Kwamandla Emhlabeni Wonke | 28% kusukela ngo-2020 kuya ku-2040 |

Lezi zibalo ziqokomisa ukuthembela okwandayo kuma-valve okulawula umshayeli we-hydraulic ekuzisebenzeleni kwezimboni, okuqhutshwa ikhono lawo lokuthuthukisa ukusebenza kahle nokunciphisa ukusetshenziswa kwamandla.

Indima ezinhlelweni ze-hydraulic ezibalulekile ngokuphepha

Izinhlelo ze-hydraulic ezibalulekile ngokuphepha zithembele kakhulu kuma-valve okulawula umshayeli we-hydraulic ukuqinisekisa ukuthembeka nokuhambisana nezindinganiso zokuphepha eziqinile. Lawa ma-valve afaka izici zokuphepha ezithuthukisiwe ezivimbela ukwakheka kwengcindezi ngokweqile futhi zigcine ukusebenza ngesikhathi sokulahlekelwa amandla.

Izilinganiso zokusebenza kokuphepha eziphawulekayo zifaka:

- Amavalvu e-Bosch Rexroth DBW aqala kabusha ngokuzenzakalelayo ngemva kokulahlekelwa ugesi, okuqinisekisa ukusebenza okuqhubekayo.

- Ukuhlolwa kohlobo lokuhlolwa kuqinisekisa ukuthembeka kwazo ngaphansi kwezindinganiso zokuphepha eziqinile kanye nokusebenza.

- Ukuthobela i-Pressure Equipment Directive (PED) kuqinisekisa ukunamathela ezidingweni zokuphepha ezibalulekile.

Lezi zici zenza ama-valve okulawula umshayeli we-hydraulic abe ukukhetha okuthembekile kwezinhlelo zokusebenza lapho ukuphepha kungenakubekeka engcupheni, njengezindiza, imishini yezokwelapha, kanye nezindawo zezimboni ezinobungozi obukhulu.

Ama-valve okulawula umshayeli we-hydraulic aqinisekisa ukugeleza koketshezi ohlangothini olufunwayo ngenkathi evimba ukugeleza okubuyela emuva. Indima yawo ekugcineni ukuzinza kohlelo, ukuthuthukisa ukuphepha, kanye nokuthuthukisa ukusebenza kahle kuwenza abe abalulekile kuzo zonke izimboni. Ukuqonda izindlela zawo kanye nokusetshenziswa kwawo kugqamisa ukubaluleka kwawo ezinhlelweni zanamuhla ze-hydraulic, lapho ukunemba nokuthembeka kubalulekile khona.

Ukuthatha Okubalulekile: Lawa ma-valve abalulekile ekufezeni ukuphepha nokusebenza kahle ekusebenzeni kwe-hydraulic.

Imibuzo Evame Ukubuzwa

Uyini umehluko phakathi kwevalvu yokuhlola i-hydraulic pilot kanye nevalvu yokuhlola ejwayelekile?

Ivalvu yokuhlola umshayeli we-hydraulic ivumela ukugeleza okuphambene lapho kusetshenziswa ingcindezi yomshayeli. Ivalvu yokuhlola ejwayelekile ivumela ukugeleza okuya ohlangothini olulodwa kuphela ngaphandle kokulawulwa kwangaphandle.

Kufanele kugcinwe kangaki amavalvu okulawula umshayeli we-hydraulic?

Ukulungiswa okuvamile kufanele kwenzeke njalo ezinyangeni eziyisithupha. Hlola ukuguguleka, imfucumfucu, kanye nokusebenza okufanele ukuqinisekisa ukusebenza kahle kanye nokuphepha kohlelo.

Ingabe ama-valve okulawula umshayeli we-hydraulic angaphatha izinhlelo zokucindezela okuphezulu?

Yebo, lawa ma-valve aklanyelwe izindawo ezinomfutho ophezulu. Ukwakhiwa kwawo okuqinile kuqinisekisa ukusebenza okuthembekile ngaphansi kwezimo ezidinga amandla amaningi.

Isikhathi sokuthunyelwe: Meyi-24-2025